Code:

Disclaimer I am not liable for any things you may do to your carBTW, it is NOT illegal to remove the crash beams or air bags

http://www.nhtsa.gov/cars/rules/adaptive/inoper/Fre_ask_ques.htm

http://www.nhtsa.gov/cars/problems/studies/bumper/index.html

Due to popular demand, I have been asked to make a list of the things I have removed, replaced, or modified to reduce weight on my Evo. I wont be able to remember everything right away so I will update this post as I remember more stuff. I still retain the dash, plastic covers for foot wells, carpet, door panels, head liner, and rear seats for a semi stock look since I drive my car on public roads.

I wont post the weight of parts removed because I did not weigh them.

So as my car sits on Aug 7, 2012

weight with a full tank of gas and my 25 pound son in the back as of Aug 18, 2012

Pics of my interior:

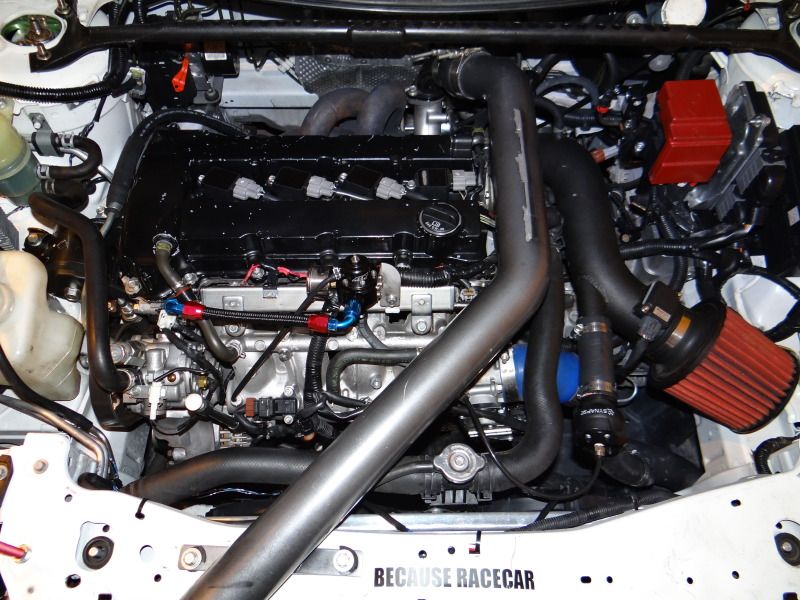

My engine bay as of Aug 13, 2012

My cars weight and engine bay as of Aug 5th, 2013

The Removed list:

- all crash beams (front, rear, and crash bars inside the doors)

- all airbags, airbag control unit, airbag sensors, and all airbag wiring

- A/C compressor, condenser, lines and core. Replaced with AMS A/C delete pulley

- fog lights, replaced with JDM fog light deletes

- all plastic panels on the front bumper (air guides, etc)

- weight below intercooler and below where the driveshaft and transfer case meet

- stock hood latch and gutted stock hood and trunk lid

- all sound deadening (in cabin and in trunk)

- entire sound system (head unit, amp, sub, all speakers, and all wiring)

- all trunk crap (carpet, plastic, fiber board, etc)

- steel frame from the rear back rest and fold down arm rest

- all floor mats

- steel plates that hold the stock head unit in place

- all brackets/bolts that aren't used or I modified them to be lighter but still as strong (far too many to list)

- stock plastic fender vents

- all fabric insulation in engine bay, firewall, and most of it in the cabin.

- unnecessary heat shields

- driveshaft tunnel heat shield and fuel tank heat shield

- black metal plate underneath the windshield wipers (no clue what its called)

- rear black plastic panel

- steel brackets above the rear strut tower

- at least 10 pounds of unused wiring from components that were removed

The Replaced list:

- stock driver and passenger seats with Bride FRP bucket seats with buddy club low seat rails

- stock steering wheel with a Works bell hub and Momo steering wheel

- front crossmember with AMS lightweight front crossmember

- stock springs/struts with JRZ RS1 coilovers with swift main & helper springs (which are 20 pounds ligher than the exact same spec Eibach springs)

- stock wheels/tires with Enkei RPF1 18x9.5 +15 with 245 Dunlop star spec tires

- stock battery with AMS lightweight battery kit

- stock driveshaft with lightweight aluminum driveshaft

- stock rear control arms with Megan racing rear control arms

- stock exhaust manifold with Full-Race Pro-stock tubular manifold

- stock turbo back exhaust with ETS recirc downpipe, custom aluminum test pipe and custom titanium cat-back

- entire stock HVAC unit with a flex-a-lite mohave lightweight heater along with heater core and A/C core (weighs less than 5 pounds rather than the 20+ pound stock HVAC unit)

- stock rear wing with a Aeromotions R2 static CF wing

- stock mirrors with APR Formula GT3 mirrors

- stock radiator and fan shroud with Mishimoto radiator and flex-a-lite 2500 cfm single fan custom mounted to radiator

- stock fuel feed line (which is steel) with lightweight -6 an fuel line

- stock clutch and flywheel with ACT 6-puck and streetlight flywheel

The Modified list:

- stock strut bar (drilled holes and cut off unnecessary metal

- stock steering column support (removed all unnecessary brackets/metal but still retaining its strength)

To Do list:

Nothing, im completely out of ideas. Feel free to post any ideas